In the rapidly evolving landscape of manufacturing, “AMS39K” the advent of cutting-edge technologies is continuously redefining industry standards. One such technological marvel that promises to revolutionize manufacturing is AMS39K. This advanced manufacturing system integrates the latest in artificial intelligence, machine learning, and the Internet of Things (IoT) to create an environment that is both highly automated and exceptionally efficient. In this article, we will explore the intricacies of AMS39K, its features, benefits, and the transformative impact it is set to bring to the manufacturing sector.

What is AMS39K?

AMS39K is an industrial-grade monitoring system designed to track and analyze key performance metrics in real-time. Built for harsh and demanding environments, this system leverages state-of-the-art sensors and data analytics to provide actionable insights into machine performance, environmental conditions, and system health. By utilizing AMS39K, businesses can prevent costly downtime, improve safety standards, and enhance productivity through proactive maintenance and monitoring.

Key Features of AMS39K

When evaluating a monitoring system, it’s crucial to understand its features and capabilities. AMS39K excels in offering advanced functionalities that cater to the needs of modern industries. Below are the standout features that make AMS39K a preferred choice for industrial applications.

Real-Time Data Monitoring

At the core of AMS39K is its ability to provide real-time data monitoring. The system collects data from various sensors embedded in machinery, equipment, or the surrounding environment. Whether it’s temperature, pressure, or vibration levels, AMS39K provides continuous updates to help businesses stay on top of their operations.

Predictive Maintenance

One of the most valuable features of AMS39K is its predictive maintenance capability. The system uses historical data and advanced algorithms to predict when a machine or piece of equipment is likely to fail. This allows businesses to address potential issues before they result in costly downtime or system failures.

Benefits of Implementing AMS39K

1. Increased Productivity

The advanced automation and optimization capabilities of AMS39K significantly boost productivity. By streamlining production processes and reducing the need for manual intervention, the system enables manufacturers to achieve higher output levels without compromising on quality. This increase in productivity can lead to substantial competitive advantages, allowing companies to meet growing demand more effectively.

2. Cost Savings

AMS39K’s predictive maintenance feature is a key contributor to cost savings. By monitoring equipment in real-time and predicting potential failures before they occur, the system minimizes downtime and reduces maintenance costs. Additionally, the system’s precision reduces material wastage, further contributing to overall cost efficiency. These savings can be redirected towards other critical areas of the business, enhancing profitability.

3. Enhanced Quality Control

Quality control is a critical aspect of manufacturing, and AMS39K excels in this area. The system’s real-time quality monitoring ensures that defects are detected and addressed promptly, leading to higher product quality and customer satisfaction. By maintaining consistent quality standards, manufacturers can build stronger brand reputations and foster customer loyalty.

4. Scalability

AMS39K is designed with scalability in mind. Its modular architecture allows manufacturers to expand their production capacities as needed. Whether scaling up to meet increased demand or adapting to new market opportunities, AMS39K provides the flexibility to grow with the business. This scalability ensures that the system remains a valuable asset as the manufacturing landscape evolves.

User-Friendly Interface

Despite its advanced features, AMS39K boasts a user-friendly interface that makes it easy for operators to access and interpret data. The system provides customizable dashboards, allowing users to display the most relevant metrics for their specific operations.

Integration with Existing Systems

AMS39K is designed to seamlessly integrate with existing industrial systems, such as SCADA (Supervisory Control and Data Acquisition) and ERP (Enterprise Resource Planning) platforms. This enables a unified monitoring experience, where data from multiple sources can be consolidated and analyzed in one place.

How AMS39K Enhances Operational Efficiency

Operational efficiency is a top priority in any industry, and AMS39K helps businesses achieve this by streamlining processes, reducing waste, and improving machine reliability. Here’s how AMS39K drives efficiency across various industrial sectors.

Minimizing Downtime

By providing real-time data and predictive maintenance alerts, AMS39K enables businesses to minimize downtime. Instead of reacting to machine failures after they occur, operators can plan maintenance activities during scheduled downtimes, ensuring that production schedules remain unaffected.

Optimizing Resource Use

AMS39K’s ability to monitor energy consumption and machine performance allows businesses to optimize their resource use. For example, if a machine is found to be using more energy than expected, adjustments can be made to improve its efficiency, reducing energy costs over time.

Reducing Operational Costs

Through proactive maintenance and performance monitoring, AMS39K helps reduce operational costs by extending the lifespan of machines and preventing expensive repairs. Businesses that adopt AMS39K can expect to see significant savings over time, both in terms of reduced downtime and improved resource management.

Enhancing Safety Standards

In industries where safety is critical, AMS39K provides an extra layer of protection by continuously monitoring key safety metrics. Whether it’s detecting hazardous gas levels or ensuring equipment is operating within safe parameters, AMS39K helps businesses enhance their safety standards and reduce the risk of accidents.

Applications of AMS39K Across Different Industries

AMS39K’s versatility makes it suitable for a wide range of industries. Let’s take a look at how different sectors can benefit from implementing this advanced monitoring system.

Manufacturing

In the manufacturing industry, where machine uptime is critical, AMS39K provides invaluable insights into equipment health. By monitoring key metrics like vibration, pressure, and temperature, manufacturers can optimize machine performance, reduce downtime, and maintain production schedules with greater accuracy.

Energy Sector

The energy industry, particularly in oil, gas, and renewable energy, relies on the system for monitoring critical infrastructure. Whether it’s tracking pipeline pressures or monitoring the performance of wind turbines, ensures that energy systems operate efficiently and safely.

Food and Beverage

In food and beverage production, maintaining optimal environmental conditions is crucial for product quality. helps monitor temperature, humidity, and air quality within production facilities, ensuring that standards are met and reducing the risk of product contamination.

Chemical and Pharmaceutical

For industries like chemicals and pharmaceuticals, where precision is paramount, offers real-time monitoring of critical parameters such as temperature, chemical concentrations, and pressure. This ensures that production processes remain consistent, and any deviations are addressed immediately.

Transportation and Logistics

In the transportation and logistics sector, AMS39K helps track vehicle performance and environmental conditions during the transportation of sensitive goods. By monitoring things like engine health, tire pressure, and cargo temperature, businesses can ensure the safe and timely delivery of products.

Why AMS39K is a Game-Changer for Industrial Monitoring

The industrial sector is undergoing a transformation driven by technology, and AMS39K is playing a pivotal role in this evolution. Here’s why is considered a game-changer for industrial monitoring:

Precision and Reliability

The AMS39K system uses highly accurate sensors to provide precise data that businesses can rely on. This level of accuracy ensures that operators can make informed decisions, ultimately leading to better operational outcomes.

Proactive Problem Solving

Unlike traditional monitoring systems, which are reactive in nature, offers a proactive approach to problem-solving. By predicting potential equipment failures and maintenance needs, empowers businesses to stay ahead of issues rather than responding to them after they occur.

Scalability

AMS39K is designed with scalability in mind, making it suitable for businesses of all sizes. Whether you’re running a small production line or a large-scale industrial facility, can be customized to meet your unique monitoring needs.

Data-Driven Decisions

The ability to collect and analyze vast amounts of data in real-time enables businesses to make data-driven decisions. With , industries can optimize everything from production processes to maintenance schedules based on actual data, rather than relying on estimates or guesswork.

Setting Up AMS39K in Your Facility

Implementing AMS39K in your industrial facility is a straightforward process. Here’s a step-by-step guide to getting started with AMS39K.

Step 1: Conduct a Needs Assessment

Before implementing , it’s essential to conduct a needs assessment to determine which areas of your operation will benefit the most from monitoring. This could include machinery, environmental conditions, or even specific production processes.

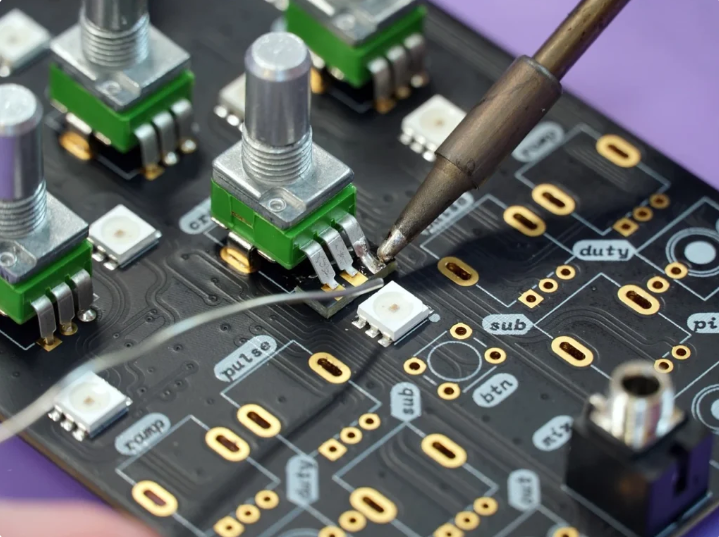

Step 2: Install Sensors

requires the installation of sensors that collect data from various points within your facility. These sensors are designed to withstand harsh industrial conditions and provide accurate, real-time data.

Step 3: Customize Your Dashboard

Once the sensors are installed, user-friendly interface allows you to customize your monitoring dashboard. You can select which metrics to display, set up alerts for specific conditions, and create reports that summarize system performance.

Step 4: Integrate with Existing Systems

integrates seamlessly with existing industrial systems such as SCADA and ERP platforms. This ensures that you can consolidate data from multiple sources and manage your operations from a single, unified platform.

Step 5: Train Your Team

To get the most out of , it’s important to train your team on how to use the system effectively. This includes understanding how to interpret data, respond to alerts, and make informed decisions based on the information provided by AMS39K.

Frequently Asked Questions About AMS39K

What industries benefit the most from AMS39K?

AMS39K is versatile and can be used in various industries, including manufacturing, energy, food and beverage, chemical production, and transportation. Any industry that requires real-time monitoring of machines or environmental conditions can benefit from AMS39K.

Is AMS39K difficult to install?

AMS39K is designed for easy installation, with sensors that can be deployed across your facility. The system is customizable and scalable, allowing businesses to choose the monitoring capabilities that best suit their needs.

How does AMS39K improve safety?

AMS39K improves safety by continuously monitoring key metrics such as temperature, pressure, and air quality. If any of these metrics fall outside of safe parameters, AMS39K sends real-time alerts to prevent accidents and ensure worker safety.

Can AMS39K integrate with my current systems?

Yes, AMS39K is build

Conclusion

represents a significant leap forward in advanced manufacturing systems. Its combination of AI, IoT, and precision engineering positions it as a critical enabler of modern manufacturing practices. As industries continue to embrace digital transformation, stands out as a vital tool for manufacturers looking to stay ahead of the curve and drive their businesses toward a more efficient, productive, and innovative future.

In summary, is not just an advanced manufacturing system; it is a transformative technology that promises to redefine the manufacturing landscape. By embracing , manufacturers can unlock new levels of productivity, efficiency, and quality, positioning themselves for success in the ever-evolving world of Industry 4.0.